Training is crucial to determining your success with our ERP system

Genius ERP will work diligently with your team to make sure you get the most out of our tools, which in turn lets you get the most out of your shop.

Training sessions can be conducted at your offices, at our headquarters, or online to any location around the globe. We will custom-tailor training sessions to address your needs and your processes.

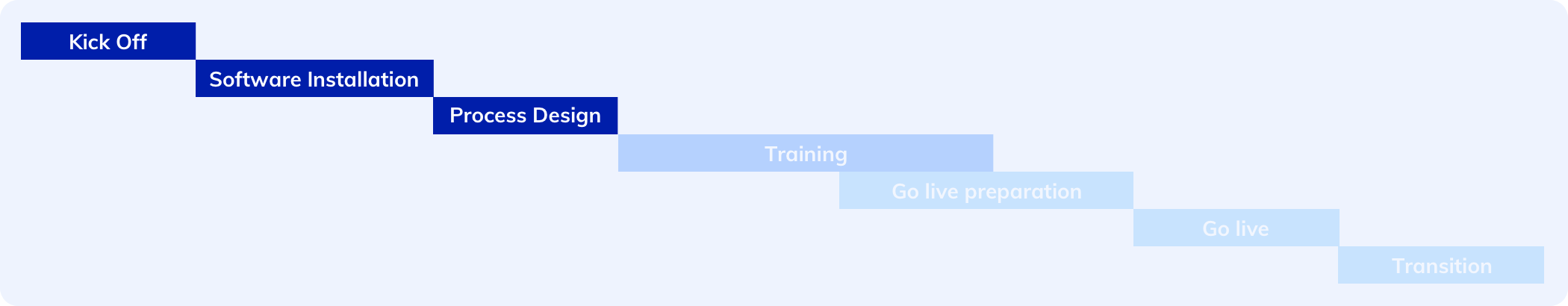

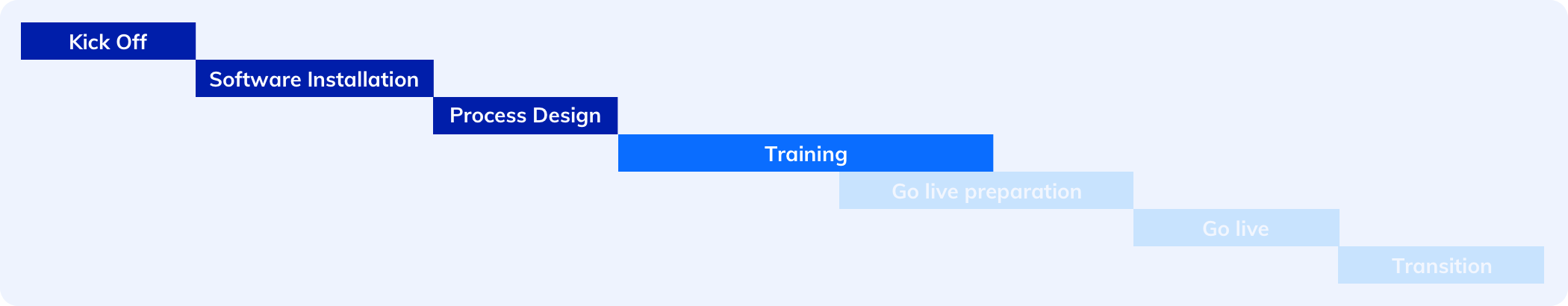

You will always be given a road-map that establishes a clear plan for where you are going, and be provided with easy-to-follow and concise documentation on how to use our system.

Our training team has decades of experience and believes in delivering active training sessions to ensure you fully understand how to get the most out of our features, so that you can increase the efficiency and profitability of your manufacturing business.