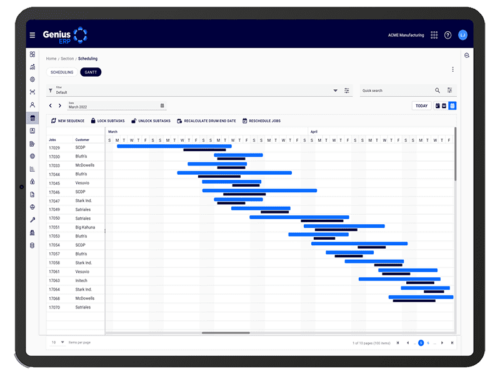

Decrease lead times

If you use a traditional manufacturing scheduling system, estimating delivery times is an educated guess at best. But Smart Scheduling lets you manage your shop more efficiently. Instead of constantly being caught in the weeds, Genius ERP’s DBR software keeps you running at maximum efficiency, meaning you can give your customers more accurate estimated delivery dates — and, more importantly, follow through and deliver on time.