Is Excel the Best Way to Track Inventory?

While you can certainly create inventory tracking spreadsheets in Excel, it is not the best option for inventory management — especially for complex manufacturers. Dedicated inventory management and control software, like that found in an ERP system, will give you more features, including integration and automation, making your inventory tracking faster and more accurate.

What is Inventory Management?

Inventory management is the overseeing of all of your inventory and stock.

It includes elements such as controlling and overseeing the ordering of inventory, storage of inventory, allocating inventory to jobs, and ensuring you are stocking the right amount of inventory to minimize holding costs and associated waste.

If you don’t have a good inventory management system in place you will have stock emergencies far too often, meaning you lack the raw materials to meet production demands — which can cost you time and money, lose you customers, and damage your reputation.

Getting a handle on your inventory management will help you avoid such situations and keep your shop up and running smoothly.

Where Excel Falls Short

Many manufacturers turn to Excel to manage their inventory as it is readily available, cost-effective, and easy-to-use.

Or so it seems.

While you may think Excel is an efficient way to track and manage your inventory, it is costing you time and money — and let’s face it — plenty of headaches too.

Excel is not a dedicated inventory management system and lacks the specificity and features manufacturers, especially custom manufacturers, need. Excel lacks the integration, connectivity, and real-time data that other types of inventory tracking systems offer.

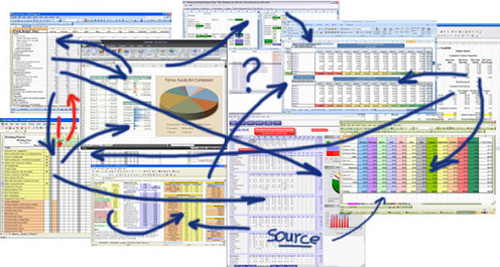

Magic Spreadsheet

Fully integrated inventory management systems, like those found within a manufacturing-specific ERP, will give you a proper inventory count — accurate to the second — meaning everyone in your shop from purchasing managers, to operations managers, to shop floor employees know what’s in stock, and where to find it.

Accurate counts will let you know what stock items you have on-hand, and what needs to be re-ordered. Integrated systems will automatically alert you when stock levels are falling low, prompting you to put in an order to ensure you never run out of raw materials.

Errors

Mistakes in your inventory counts aren’t just frustrating — they can easily throw off your planning and production. Unfortunately, Excel, unlike an ERP system, is especially susceptible to human error because it is an extremely manual tool. More sophisticated inventory management systems will let you track inventory through barcode scanning — not only eliminating human errors, but also making it easier to have accurate inventory counts.

No Real-Time Data

Excel lacks the real-time inventory data that an ERP inventory management system will give you. With real-time data you will always have an accurate inventory count. Not only does this make tracking and counting your inventory easier, but it also makes it easier to plan jobs, allocate inventory, and efficiently manage the purchasing process.

No Automation

The only way your inventory can be accurate when using Excel is if someone goes in and manually updates your information every single time a part is used — which is unrealistic. An ERP system can save you time and money by eliminating the daunting task of manually processing inventory management. With an ERP system almost everything is automated saving you time and money.

A Better Alternative

Even if you have good inventory management habits in place, if you don’t have a dedicated inventory management system you are costing yourself money, and holding your business back.

How ERP Systems Help Inventory Management

As a custom manufacturer, using an ERP system for inventory management is one of the smartest decisions that you can make. Not only will you avoid the pitfalls of using a spreadsheet, but your inventory will also automatically be integrated with all aspects of your operation from planning through operations, production, and accounting.

You will be able to manage your entire operation from one system, and make your organization more organized, streamlined, and efficient.

Benefits of ERP Inventory Management

1. Integration

If your inventory management system isn’t integrated with the rest of your organization, you will never effectively optimize your inventory.

An ERP integrates your inventory management with the rest of your operation, making tracking inventory throughout your organization easy. An ERP system gives your staff instant access to a centralized inventory database that’s updated in real-time.

This lets you know exactly what you can or can’t fulfill, what raw materials you have on hand, as well as gives you the confidence that what is recorded in the database matches what is sitting on your shelf, making not only production more efficient, but financial reporting easier as well.

2. Streamline Business Processes

Accurate inventory management can help increase a manufacturer’s overall efficiency. Employees can spend their time on other tasks instead of, for example, trying to locate one particular piece of stock.

With an ERP system you can automatically keep track of the inventory you use on each job, which for example, will let you do proper production planning as you know exactly the amount of raw materials you have on-hand, and what you need to order to complete a job.

3. Forecasting, Restocking, & Managing Excess Inventory

An ERP system keeps track of sales, purchasing, and logistics for you so that you can have the right inventory levels to match your business needs.

With an ERP you can take advantage of an inventory management system that is in sync with the rest of your operation, which makes it easier for you to manage things like long lead-items, as you can know about these items during the design phase of a project, and have more lead time to order the item and ensure you have it in time.

Knowing real-time stock levels also make it easier to replenish inventory — an ERP can either automatically reorder materials for you, or send your purchasing manager a timely reminder letting her know that items need to be reordered.

Without an ERP telling you that it’s time to replenish inventory, manufacturers can face enormous costs to expedite freight when they are desperately in need of stock.

And having insight into surplus inventory in real-time means you might have the opportunity to return stock instead of taking up shelf space that something more important could be using.

Save Time and Money With an ERP Inventory Tracking System

Every business owner knows that efficiency equals cost savings. Using an ERP for inventory management reduces overall workload and minimizes expenses. Better managed inventory also equals more jobs out the door on-time and on-budget.

ERP inventory management systems are designed to reduce manual labor, by automating and streamlining processes — all of which go hand-in-hand with growing a business. And ERP systems let you collect better quality data, which gives you insights into your business to help you track your business performance and plan for growth.

Make the switch from Excel to a fully integrated and automated inventory management system. Get a free demo of Genius ERP to see how it will improve your inventory tracking and make your manufacturing business more efficient.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields