Excel is a one-size-fits-all business tool that is good at many tasks — but not great at any of them. Many of the things you can do with Excel are made easier, more effective, and more intelligent with a targeted tool like an ERP system.

6 Shortcomings of Excel

1. The Magic Spreadsheet-Effect

One of the things we overhear a lot from manufacturers is “everything is in the magic spreadsheet” or “we just use a magic spreadsheet to manage our shop.”

What this means is that a lot of manufacturers are relying on one, or a series of Excel spreadsheets, and one person (who created and knows how to use the “magic spreadsheet”) to manage their business.

The problem with this is that the magic spreadsheet’s owner is the only one who really knows how it works, and if this person leaves the organization, or even goes on holiday for a couple of weeks, everything can grind to a halt.

Excel is a good business tool, but it’s not good enough to rely on a single spreadsheet, or a single person to manage a complicated manufacturing business.

2. Inefficient Data Entry

A major problem with Excel is that you need to constantly re-enter data, making it an inefficient tool.

For example, if you’re writing all of your quotes in Excel, then you probably have to manually create sales orders from these quotes in a separate spreadsheet or system.

With Excel, every report, or quote, or order has to be created manually sheet by sheet — meaning you are constantly re-entering data. Additionally, the only way your inventory can be accurate is if someone goes in and manually updates your information every single time a part is used — which is unrealistic.

3. Poor Collaboration

Another problem with Excel is that it creates ‘information silos’ which makes it difficult to collaborate between departments.

Though there are mobile versions of Office and Excel available, and even cloud-based Excel spreadsheets at Microsoft OneDrive, these products have distinct disadvantages and do not always support collaboration and remote work — something that is more important now than ever.

For instance, it is difficult to control spreadsheets and maintain accuracy when multiple workers try to access and alter the Excel document at the same time.

4. Human Error

Let’s be honest, human error can creep into any system that is used by people, but Excel is especially susceptible to human error because it is an extremely manual tool.

Multiple studies back this up: According to a report from the University of Hawaii, 88% of spreadsheets contain errors; Coopers and Lybrand found that 90% of all spreadsheets with 150 rows or more held errors; and in a sample of 22 spreadsheets, KPMG found errors in 91% of them.

Excel is also based on formulas and functions to manipulate data, which is another place where human error can creep in. Even if you have an ‘Excel hero’ who runs the ‘magic spreadsheet’ in your office, and knows the product inside and out, if a function is accidentally misentered you’ll end up with bad data.

And there is also always a risk that someone can unwittingly break a function, which can cause you unwanted delays, especially if your Excel hero happens to be out of the office and can’t immediately fix the problem.

5. Insufficient Data Control

Do multiple departments within your organization rely on different sets of Excel spreadsheets that contain the same data?

The problem with this is that the same data will be entered multiple times into multiple spreadsheets — meaning not only is that a huge waste of your staff’s time — but there is also a much greater chance for human error to creep in, as each time the data is manually entered there is a chance for a data entry mistake.

And once a set of spreadsheets get printed or shared around, you lose all control over them.

As there is no single source of truth for your data, you can neither be certain about what changes have been made to your data or if everyone is relying on the right set of data.

For example, your production department might be relying on an old set of spreadsheets, or on sheets riddled with inadvertent errors, which can cause excess waste and throw off your entire production line.

6. Inadequate Data Analysis

Understanding your financial information is important to keeping your company in the black — but Excel can’t give you the real-time integrated financial workflows that can automatically collect billing data from every area of the organization.

An integrated system, like an ERP, gives you a centralized system for all financial activities including month-end, invoicing, supplier payments, and payroll, meaning you can always have a real-time understanding of what your financials are — and you’ll know what jobs are putting you in the black or red.

The manual processes inherent to Excel just can’t power this type of analysis — meaning you are always behind the eight ball when it comes to making effective business decisions.

Should You Replace Excel?

In a word, yes.

Excel is a good business tool that can do a lot of different jobs and support a lot of different functions, but it’s not equipped to manage the intricacies of a custom manufacturing business.

You need to replace it now.

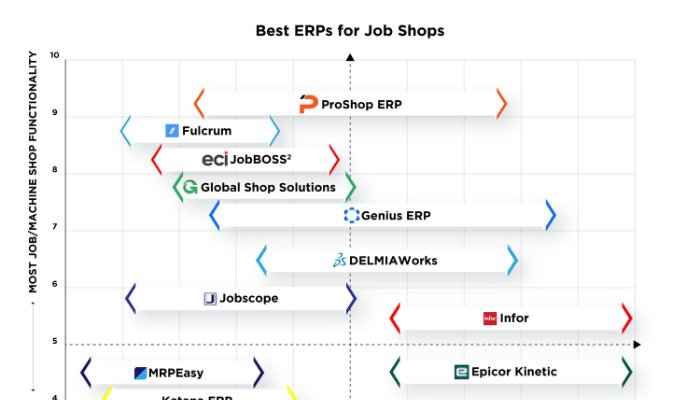

As the above list shows, there are too many problems with Excel to rely on it to run your custom manufacturing business. You need a more targeted and integrated system that runs off of real-time data to efficiently and effectively manage your manufacturing shop — you need an ERP system. (Click here to learn the ROI you can from an ERP system, and why it’s one of the best business decisions you can ever make.)

An ERP system will manage all aspects of a business, including production, planning, purchasing, manufacturing, sales, distribution, accounting, and customer service, from one fully-integrated system.

And, one of the greatest advantages of an ERP system is its ability to provide complete visibility of your operation, making it easier to manage your business and giving you insights into how your operation is performing.

With an ERP, what used to take hours of sifting through spreadsheets and manual report creation, can be done automatically, providing you with a sweeping overview of your operation, allowing you to measure critical performance metrics through real-time dashboards — and to run a more efficient manufacturing business.

Some of the many benefits of an ERP system include:

- Reduced human error

- Better inventory control

- Integrated and automated business processes

- Reliable real-time data

- Optimized production schedules

- Better business analytics

- Increased collaboration

- Better decision-making prowess

- Increased throughput

- Better data control

- Maximized capacity

Are you ready to replace Excel and upgrade to an ERP system? Get a free demo of Genius ERP to see how it will improve your business.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields