Why Do Engineers Need an ERP?

Engineers need an ERP system that has their unique needs in mind, including creating and managing Bills of Materials (BOMs), routing steps, and work instructions. Engineers also need an ERP that allows for the seamless integration of a CAD system with the ERP.

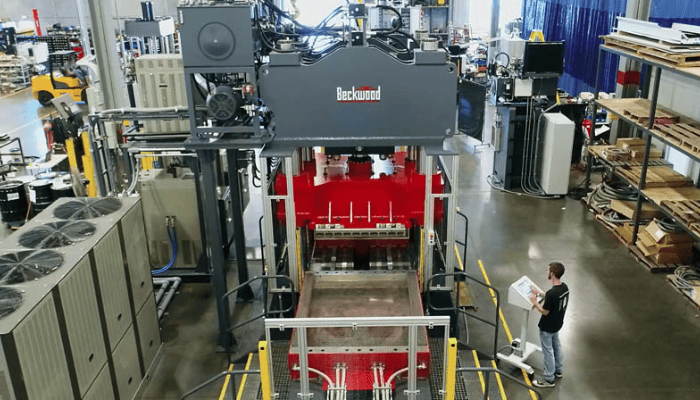

The engineering department, especially within ETO (engineer-to-order) and custom manufacturing environments, is one of the most critical departments in a manufacturing shop. Highly customized work means a lot of engineering time is needed on every order that passes through these types of shops.

But all too often, ERP systems leave engineers out and don’t include the features they need to get their jobs done efficiently or to integrate them better with the rest of your departments.

In a typical shop, transferring BOMs out of a CAD system and into an ERP may take up to 20% of total engineering time. This means that engineers are tasked with hunting down and reentering information into multiple systems. This not only wastes valuable time and increases the chance for human error, but it also decreases the productivity and efficiency of the engineering department because instead of focusing on more productive tasks, engineers are doing data entry.

ERP Benefits for Engineers

ERP systems have many benefits for engineers as they can speed up job progress, save on engineering time, increase communication between departments, and improve engineering and manufacturing processes.

Many ERPs, even those designed for the manufacturing industry, all too often leave the engineering department out of the loop. Most manufacturing ERPs will connect many departments and functions in a shop—accounting, purchasing, scheduling, and inventory management, to name a few. But, the engineering department, which plays a key role in the designing, engineering, and manufacturing of a product, is left out.

Including and integrating the engineering department into the ERP system, and by extension the rest of the organization, has many benefits and allows for the sharing of vital information between departments, and even with customers:

Sales:

- Define cost to share with sales

- Define compatible options with sales

Production/Purchasing:

- Deliver a BOM with routing steps and work instructions

- Share progress of designs/concurrent engineering

- Track milestones and feedback on achievements

- Make and track revisions

Accounting:

- Share and allocate R&D and project-specific time

Customers:

- Share drawings and estimates for approval (customer design reviews)

- Share project progress

CAD Integration

One of the most cumbersome and detailed tasks of the engineering department is to create the BOM. Many manufacturing ERPs will require the engineering department to painstakingly take a CAD model and make a list of all the parts needed, and then create the BOM, along with the routing steps and work instructions. To get this information synced up with the rest of the ERP, it must also be re-keyed into the ERP system.

Inefficient, to say the least.

The best manufacturing ERP systems will do this for you by connecting your CAD software to your ERP. This saves you all of the above steps and lets your ERP interact directly with your CAD software.

ERP systems built to work with CAD software can automatically extract and create a BOM from the designs, drawings, and models that your engineering department creates in CAD—which saves your engineers time and streamlines purchasing, requisitioning, and manufacturing processes.

Your engineers or drafting technicians will no longer need to waste hours manually creating BOMs. You can be assured that fewer errors will be made and that your BOMs will be connected to vital systems like inventory management—meaning it’s easier for you to know what parts are needed and what components must be ordered to get a job built and out the door.

During the design phase, while your engineering department is still busy at work designing and engineering a new product, your procurement team can have access to the BOM to see what critical long-lead items are needed. In this way, you can place the order early on, giving you time to get your hands on these parts, before production begins.

ERP Module for Engineers

Genius ERP’s Product Engineering module accelerates job progress with more integrated engineering and CAD2BOM.

With Genius Product Engineering you can:

- Engineer from scratch, or use historical data to design custom products and anticipate resource requirements with greater accuracy

- Generate drawings/models, attach documents in the ERP

- Breakdown your engineering design into multiple/concurrent releases to make on-time delivery

- Manage revisions

Genius ERP’s CAD2BOM feature makes it simple to directly transfer your BOM from your CAD program into Genius ERP with a click of a button, creating a fully itemized, complex BOM. Not only does this save you time, but it also ensures that you eliminate human error that can occur from having to re-enter data.

Genius ERP also makes it easy to manage complex BOMs, letting you edit and manage your imported BOM with ease, adding the required layers of detail that you need. And because your BOM is housed within your ERP, you can ensure everyone in your shop works off the latest and most accurate version.

Want to see how Genius ERP can help custom manufacturers save on engineering time and increase productivity? Check out our case studies.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields