There’s no denying that transportation equipment manufacturing is a key economic driver for industrialized countries around the world. Whether it’s motor vehicles and parts, aircraft and aerospace, trains and railways, or ships and boats, the vessels and vehicles that move us are made up of moving parts that drive your clients’ business. Transportation equipment manufacturers are deeply connected to suppliers in other industries, including manufacturers of metal products, communications equipment, plastics and rubber products, and more. And since every partner also has to respond to the needs of businesses focused on transporting passengers or goods, ERP for the transportation manufacturing industry is worth every penny and every bit of effort to get right!

A little perspective

Quebec’s transportation equipment manufacturing industry employs over 63,000 workers, who work for about 500 businesses in the Greater Montreal area. Sixty-three percent of jobs in the industry are in the aerospace product sub-sector, representing over half of aerospace manufacturing jobs in Canada. Meanwhile, Ontario accounts for over 90% of the country’s jobs in motor vehicle and parts manufacturing. And if we look at it globally, the transportation equipment manufacturing industry generates approximately $4 trillion in revenue annually, with about $750 billion of that coming from the US. No matter how you slice it, that’s a lot of jobs, expectations, and dollars to keep track of.

Challenges: transportation manufacturing

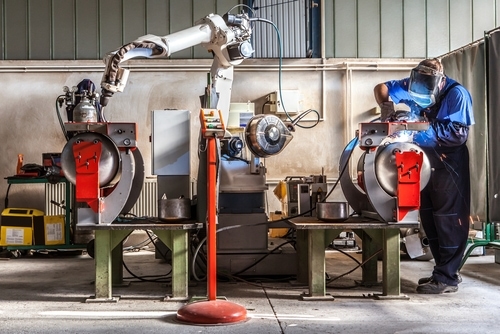

ERP features for manufacturing SMEs need to address business process management head on for SMEs that provide standard, configure-to-order, or even engineer-to-order products. Missing parts or raw materials required for production are hard to track on the best of days. High inventory issues are begging for a quality inventory management system. Production bottlenecks and supply chain challenges are the results of less-than-optimal (human-reliant) coordination. All of the above have a significant bearing on your company’s reputation. Whether you are a specialty vehicle builder, an original equipment manufacturer, or a Tier 1 or 2 supplier, your business functions can get complicated fast.

Solutions: ERP features for manufacturing SMEs

With the right ERP for transportation manufacturing, it’s possible to improve operational processes by managing new builds, repairs, or selling parts with renewed finesse. What you want is to become a reliable supplier, increase work orders, and take low production run margins higher. You need an easy-to-navigate matrix to compare pricing and compatibility data, as well as manage and integrate every single other business function you’ve got, from materials to sales, orders, finances, production, supply chain, and customer relationships. You need financial reporting that provides real-time coordination of activities across your entire business. After all, what your clients deliver to their customers and suppliers is what shapes their reputation. ERP for transportation manufacturing can ensure they deliver efficiency, simplicity, consistency, and a spirit of collaboration.

To break it down, must-have ERP features for manufacturing SMEs in transportation equipment include:

- Configuration management: so you can project how you are going to meet customer requirements, by analyzing all production details. A great configuration management tool interfaces with product engineering to keep data fresh. A CAD-2-BOM feature lets you deftly synchronize design with factory production, thus providing options to dealers and increasing your likelihood of up-selling/cross-selling with accurate pricing.

- Engineering management: helps you keep track of changing requirements and project adjustments along with your associated resolution processes. Modern ERP can highly standardize and automate change management and approval steps, maintaining an efficient, hassle-free workflow. This feature also allows you to make immediate adjustments.

- Project management: lets you control the many production components, complete with planning and tracking functions like acquiring VIN tracking and warranty information, or tracking serialized parts by lot and date codes through the value stream from start to finish. You can also make planning less complex with intuitive tools that turn engineering and quote details into project workflows.Or, save projects as templates and repurpose them!

- Asset management: for collecting and analyzing data associated with your production machinery, equipment, specialized vehicles, and other assets. This about ensuring preventive maintenance based on data insight, and keeping machinery running reliably at top performance. You can also quickly create repair jobs or schedule service calls when required.

Procurement management: for better scheduling capabilities. Install demand-based procurement for a lean, optimal manufacturing approach. Also, imagine managing formal agreements with suppliers, ongoing supplier relationships, and the purchasing of goods and services by working seamlessly with accounts payable to process supplier invoices efficiently.

Learn more about the benefits of Genius Solutions’ ERP for transportation manufacturing here.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields