What If Scheduling — the newest feature included in Genius ERP’s Smart Scheduling system — will make it even easier for you to schedule your shop!

The Rescheduling Problem

Rescheduling is a major problem that manufacturers, especially custom manufacturers, are constantly dealing with. Rescheduling is the process of updating an existing production schedule in response to disruptions or other changes. This includes the arrival of new jobs, changes from customers, or production-floor problems such as machine failures or maintenance.

The problem with rescheduling is that it can throw off your entire shop, causing you to fall behind on jobs, deliver late, and make your customers unhappy.

Learn how you can use our Smart Scheduling system — now including What If Scheduling — to solve this problem.

What is Smart Scheduling?

If you’re new around here, you might need a quick introduction to our Smart Scheduling system. Smart Scheduling was designed specifically for custom manufacturers and is the future of shop floor scheduling.

It is the only DBR (Drum-Buffer-Rope) scheduling system within an ERP. Instead of relying on bad data like traditional scheduling systems, Smart Scheduling creates a shop floor schedule based on how your shop actually runs — and always creates an accurate schedule that ensures you are always running at maximum efficiency.

Click here to learn more about Smart Scheduling or watch this video to see how it will change your shop.

What is What If Scheduling?

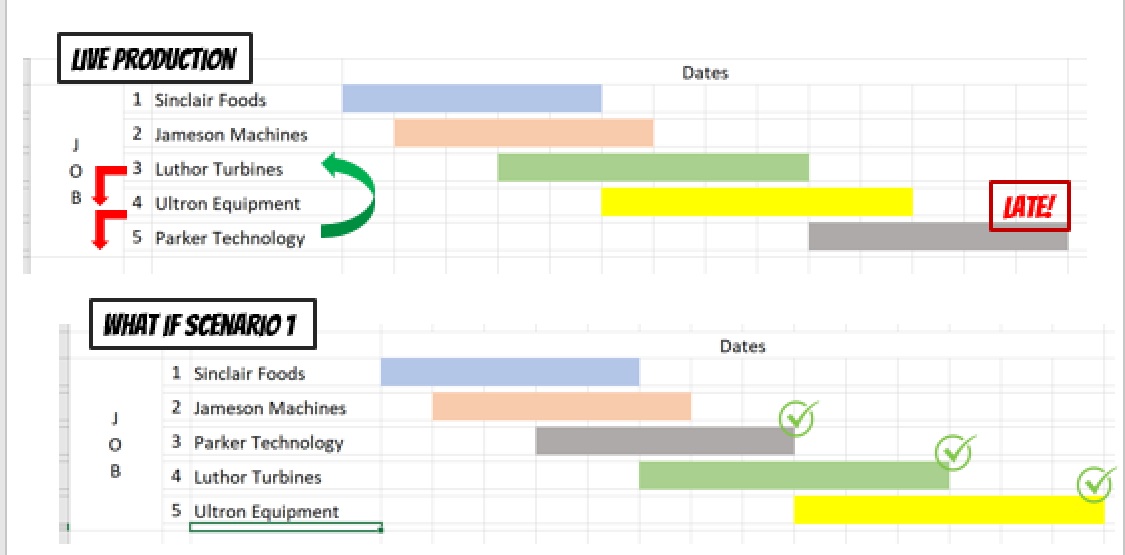

What If Scheduling allows you to easily deal with changes and shifting priorities — whether from a customer request, a new order, or a late delivery from a 3rd-party vendor. Before you change your schedule and disrupt all the current jobs you have in progress on your shop floor, What If Scheduling runs simulations for you, so you can see the impact of a change before you make it.

What if Scheduling lets you test the results of adding or moving jobs, without impacting your shop environment, until you find the schedule that works best—the one that balances all of your priorities and ensures on-time delivery.

How to Use What If Scheduling

What If Scheduling is easy to run in your shop — just run the simulation to see the effects of any change you want to make. The system will calculate new milestones, run the material plan using the new milestone dates, and create a report for you.

The What If Scheduling module now considers production material in its simulations, which enables you to confirm if the material is available before committing to the scenario and changing priorities on the shop floor. The simulation was simplified to use a reservation date in relation to a predetermined milestone. If there is no milestone, the job start date will be used.

The report will then enable you to confirm the result of the simulation, and you will then be able to decide if you want to proceed with the change. In this way, you will be able to see the effect of making the change before having to commit to it. You can run multiple simulations until you find the right scenario that works best for your shop — and ensures you deliver your jobs on time.

Benefits of What If Scheduling

See the results before making a decision:

- Simplify scheduling to make better decisions

- Deliver more jobs on time

- See the impact of a change before committing and impacting all users

- Start from an existing scenario to improve results

- Confirm a delivery date and see the impact on other sales orders

- See the impact on shop floor loading

- Know the material availability to confirm if a scenario is realistic

- Use the only scheduling system for ETO/MTO manufacturers based on DBR Theory

- Scenario management system can create infinite scenarios

- Get the results for a new sales order, or forecast future sales orders before impacting the entire system

—-

Learn more about Smart Scheduling, now including What If Scheduling, here, or book a free demo to see Genius ERP in action and what it can do for you!

Get your eBook Scared to implement a new ERP?

"*" indicates required fields