Marathon Equipment

With too many manual processes, Marathon needed an ERP that could update and automate their operation.

If you’ve spent any time looking into ERP systems or manufacturing software, you’ve probably come across the phrase ‘real-time data’ more times than you can count. It sounds important—but what does real-time data actually mean for manufacturers, and why does it matter?

If you’re a manufacturer, especially one juggling a busy shop floor, changing schedules, and tight deadlines, real-time data isn’t just another industry buzzword. It’s a tool that can change how you run your business day to day.

We break down what real-time data means for manufacturers and the difference it can make in your shop. You’ll learn how real-time data is different from traditional reporting, why it’s critical for better decision-making and shop floor control, and how an ERP system makes it all possible. Plus, we share real-world examples from manufacturers who are using real-time data to work smarter, improve accuracy, and grow their businesses.

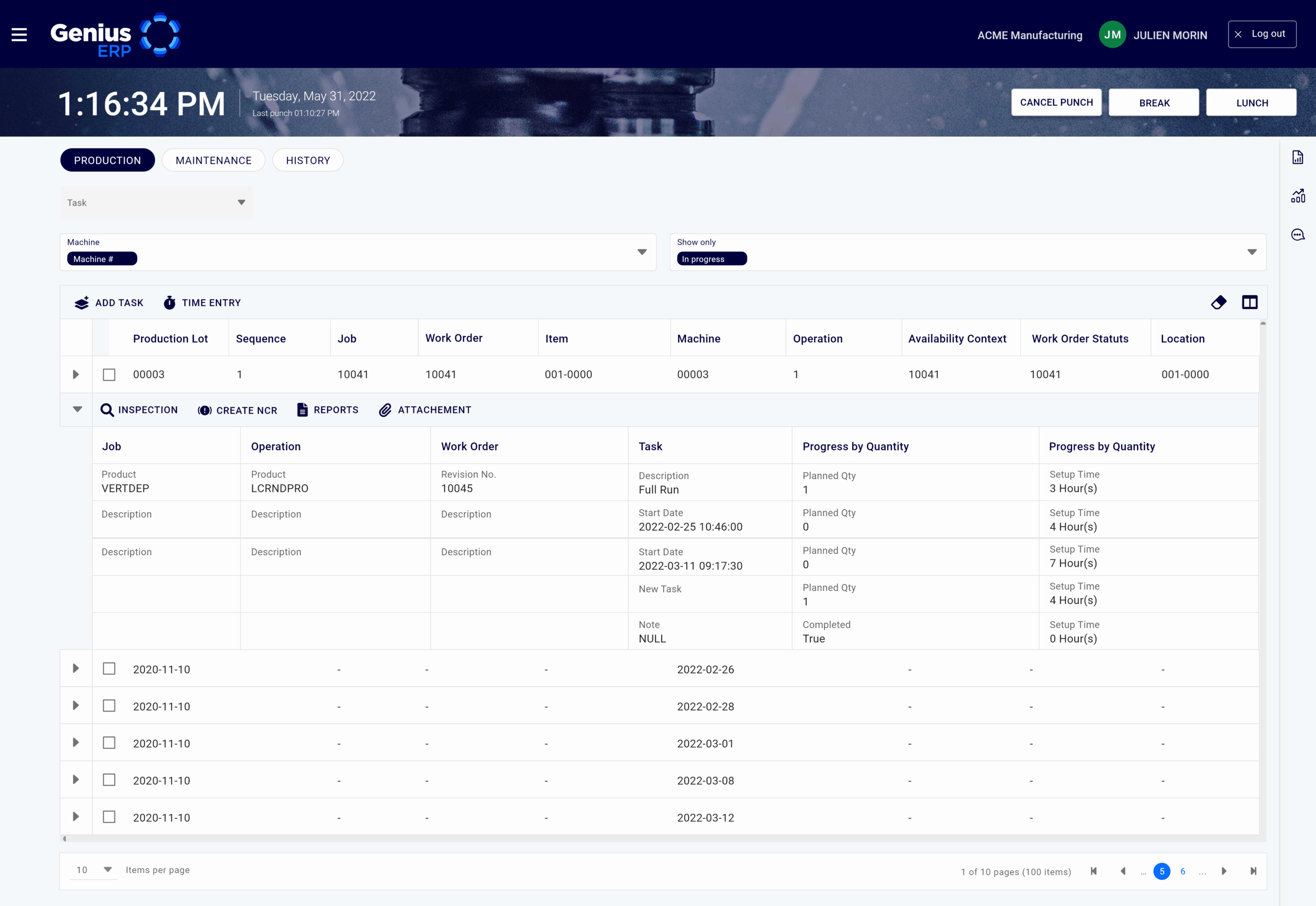

Real-time data in manufacturing means getting live updates on production, inventory, and job status the moment they happen, so you can make faster, better decisions without delays.

Real-time data is exactly what it sounds like: information that’s available as soon as it’s generated. No waiting for reports to run overnight. No emailing spreadsheets back and forth. No walking across the floor just to get an update from someone. Instead, you get up-to-the-minute insights into what’s happening across your shop.

The opposite of real-time data is what most manufacturers are used to: delayed or ‘batch’ reporting. That’s when someone pulls a report once a day—or once a week—and sends it around. By the time you read it, the numbers are already out of date.

And if you’re using spreadsheets to track things like job progress or inventory? You know how quickly those fall behind or how often someone updates the wrong cell and throws off the entire sheet.

In contrast, real-time data gives you a clear picture of what’s happening right now, not what happened yesterday, so you can act fast and always know where things stand.

You don’t need data just to have it—you need it so you can use it. That’s what makes real-time data so valuable. Here’s what it actually does for your shop:

Whether you’re a production manager adjusting schedules or a buyer deciding when to reorder parts, up-to-date data helps you move quickly—and with less second-guessing. You can make calls based on facts, not hunches.

Real-time inventory visibility helps you stay on top of what’s in stock, what’s on order, and what’s needed. For example, Marathon Equipment used to rely on visual checks to keep track of inventory, which led to frequent shortages and production delays. Now, with live ERP updates, they’ve eliminated emergency stock-outs and can keep production moving without last-minute scrambles.

With too many manual processes, Marathon needed an ERP that could update and automate their operation.

When everyone—from sales to the shop floor to purchasing—works off the same live system, communication improves. Real-time data eliminates the need for constant check-ins. Everyone sees the same numbers at the same time.

Instead of finding out after the fact that a job is late or a machine went down, real-time alerts let you spot issues early and jump on them. Jennison, for example, uses live scheduling and production tracking to keep jobs on time and customers happy. Since switching to Genius ERP, they’ve cut late orders by roughly 30%.

To get real-time data, you need the right tools—starting with your ERP system. A good manufacturing ERP system is designed to be your single source of truth. It connects your departments and processes in one place—and it updates in real time.

Here are a few ways it does that:

Take Machitech. Before switching to Genius ERP, they were tracking inventory with spreadsheets, which led to mix-ups and delays. Now, with real-time tracking through QR codes, they always know exactly what’s in stock—no more guessing, no more surprises. By using real-time data to improve their processes, they scaled from building 30 machines a year to over 250.

Jennison saw a similar transformation. They used to quote jobs using a flat hourly rate, basically guessing what each job would cost. Now they track labor, tooling, and machine time as it happens, which lets them quote more accurately—and win more jobs.

At Marathon Equipment, real-time data has played a big role in their growth. With full visibility into inventory, purchasing, and production, they grew 20% in just one year—and they’re already planning for another jump.

Real-time data gets tossed around a lot in software demos—but it’s more than just jargon. It’s the difference between reacting late and making smart decisions right when they matter most.

Manufacturers today need to move fast. You need live data to manage your schedule, materials, and shop floor—so you can move faster, work smarter, and deliver on time.

That’s what companies like Machitech, Jennison, and Marathon have figured out. They’re using real-time data not just to make better calls—but to grow, cut waste, and improve accuracy across the board.

Still relying on spreadsheets or weekly reports? You’re not seeing the full picture—and your shop is missing out.

Want to see how real-time data could work in your shop?

Book a free demo of Genius ERP and explore live dashboards, job tracking, and inventory alerts—all in real time.

"*" indicates required fields