It’s not news that ERP features for manufacturing SMEs help companies solve their operational issues, both large and small, on whole new levels. Integrating an ERP system into your manufacturing operations can be an indispensable strategy for reducing costs, optimizing production processes, and significantly increasing the odds that your company will continue to grow and evolve longer term. The majority of businesses nowadays are finally prioritizing “going digital” and all it entails. The fact is, ERP systems must continue evolving in order to fulfill businesses’ ever-changing needs.

Global ERP Software Market is expected to amass $41.69 billion by 2020, registering a CAGR of 7.2% during the 2014-2020 forecast period.

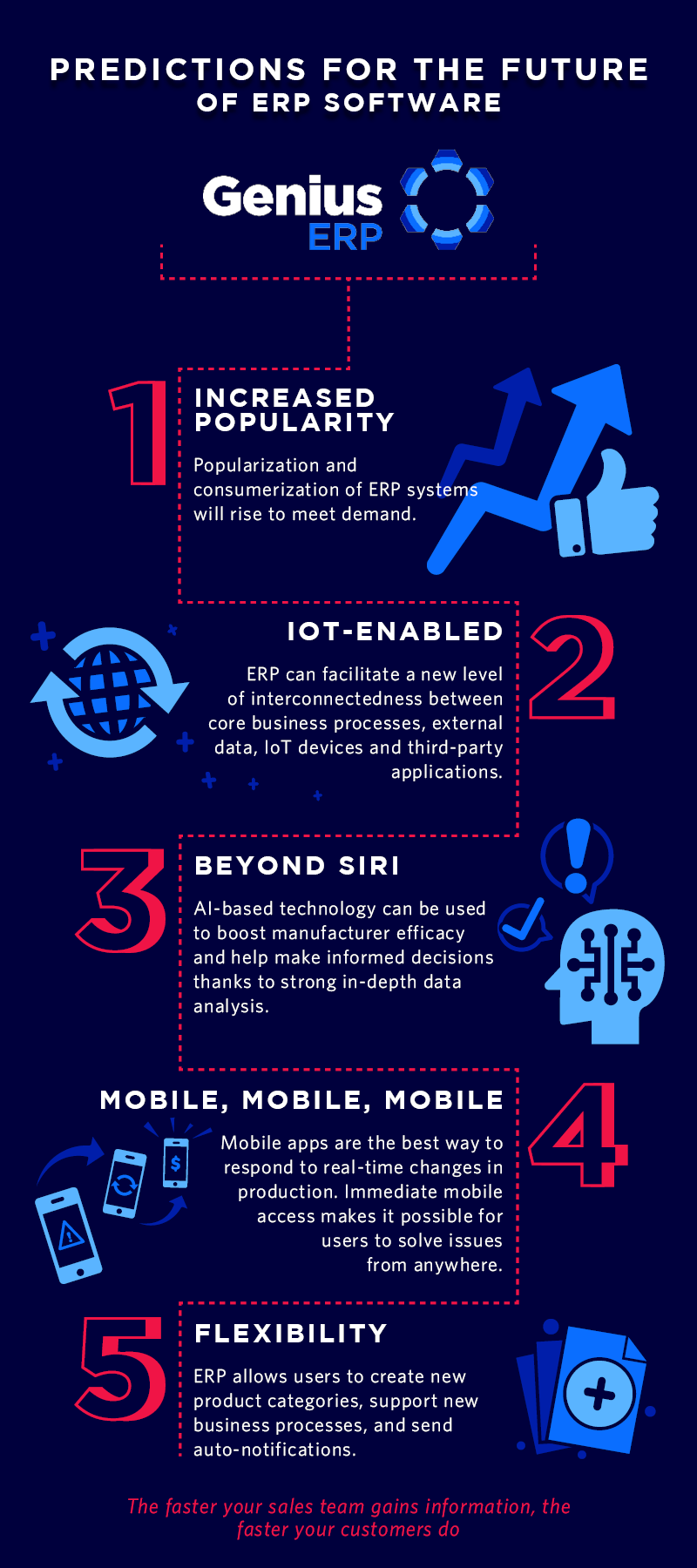

Here are 5 future trends in ERP systems that help illuminate the future of ERP features for manufacturing SMEs:

1. The increased popularization of ERP systems

As fresh, new generations of employees continue to enter the workforce, the popularization and therefore consumerization of ERP systems will likely rise to meet their demand for systems that aren’t run on obsolete technologies. Similarly, ERP vendors that still develop and support outdated user interfaces will face increased pressure to create user-friendly, intuitive features. This means prioritizing ERP features for manufacturing SMEs that resemble consumer technologies more closely.

2. IoT-enabled

ERP can facilitate a new level of interconnectedness between core business processes, external data, IoT devices and third-party applications. IoT-enabled manufacturing ERP can easily link and sync your office with your shop floor. No looking back. API-supported ERP systems can receive data from further down an assembly line and send real-time alerts. Our customers in trailer manufacturing appreciate this improved communication. Such a system can also take charge of inventory control, delivering data to the ERP backend in real-time, instantly updating inventory balances and cost calculations to keep your numbers accurate.

3. Beyond Siri

When it comes to future enhancements of ERP systems, AI’s the word. More and more businesses are catching on. Siri and Alexa have brought us a long way in our quest for hassle-free phone calls, reliable alarms, and effective searches. But AI-based technology can also be used to up your efficiency as a manufacturer. An AI-based, voice-activated personal assistant can be invaluable to manufacturers, making it far easier to make an informed decision thanks to strong in-depth data analysis. The automatic analysis of shop floor data also helps streamline production by identifying problems or irregularities on the spot.

4. Mobile, mobile, mobile

Although demand for cloud-based solutions has garnered industry attention, mobility will likely be the primary technological reality ruling ERP features for manufacturing SMEs by 2020. Mobile apps are undeniably the best way to respond to real-time changes in production. Having immediate mobile access on the shop floor makes it possible for users to cope with line problems on the spot, reducing wasted resources and materials. Managers, even while off-site, can ensure operators are following production schedules and instructions, or issuing maintenance orders. Supervisors can access product availability or change work data on the spot. What better way to stop a problem in its tracks?

5. Flexibility

If you’re in manufacturing, you know better than anyone that highly efficient production and turnaround times are a necessity. It’s hard to predict how your business processes will look in the coming years. ERP for transportation manufacturing or any other manufacturing industry needs to facilitate a reliable stream of top-tier parts. But amid constantly changing product configuration, suppliers, partners, and of course, customers, flexibility is a necessary asset. Worthwhile ERP allows users to create new product categories, support new business processes, and send auto-notifications when a product is ready for shipping. The faster your sales team gains information, the faster your customers do.

Future trends in ERP systems play a special role in today’s growing market trends and requirements. ERP features for manufacturing SMEs must be able to connect devices, departments, partners, suppliers, and your loyal customers in one versatile database. Before we know it, AI-powered ERP for transportation or other manufacturing industries will do a lot more than simply track every aspect of your business. It will go one step further and actually provide recommendations for improving and optimizing at every level, becoming the real brains behind the operation!

Discover the competitive advantages of Genius Solutions’ ever-evolving ERP features for manufacturing SMEs here.

Get your eBook Scared to implement a new ERP?

"*" indicates required fields